Analysis of ship resistance is carried out using the maxsurf software with Savitsky and Slender Body method as shown in the graph below.

Analysis of ship resistance is carried out using the maxsurf software with Savitsky and Slender Body method as shown in the graph below.

By entering the radius of gyration value from the results of the previous post calculations, then seakeeping analysis is carried out with a speed criteria of 30 knots, heading angle 180°, and adding the Bretschneider or ITTC wave spectrum criteria to the maxsurf software, the results of seakeeping analysis in RAO graph generated as in the picture below

Ship motion prediction programs such as maxsurf require a ship’s radius of gyration (or gyradius) around the longitudinal, transverse, and vertical axes passing through its center of gravity. The gyradius is defined as the square root of the ratio of total rotational inertia to mass for each axis:

xi= longitudinal origin distance to center of gravity

xi= longitudinal origin distance to center of gravity

yi= transverse distance origin to center of gravity

zi= vertical distance from origin to center of gravity

wi= mass of each element (section)

Calculation table:

So the calculation becomes as follows:

The value results calculated above will be used in the next post session.

Curve of sectional area (CSA) is a curve that shows the area of the ship at each station as shown below

In order to ease the hydrostatic analysis process, this ship’s design was enlarged 30 times. Comparison of dimensions, wetted surface area (WSA), volume, and displacement between scaled ships and ship prototypes are listed in the table below. The principal dimension scale does not apply to all quantities. To calculate other variables such as speed and force, we use the comparison formula of the scale factor based on Froude’s law about the similarity of geometric, kinematic and dynamic aspects in both objects.

Then, the scaled model was imported in the maxsurf software to analyze its hydrostatic properties. the ship’s model and the results of the hydrostatic calculation are in the picture below

In order to get the results of the ship’s frame components that have good quality and neatness, we use laser cutting machine as a tool to cut plywood used as a frame material for ship’s prototype.

For that we made a “Laser Cutting Design” of the plywood using AutoCAD 2015. the results of cutting design and laser cutting results can be seen in the picture below.

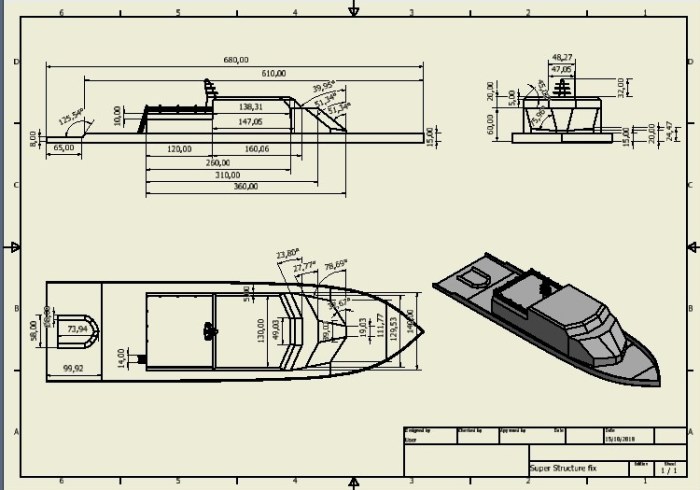

Superstructure Design was completed using Autodesk Inventor Professional 2015. The picture shown above represents the superstructure design.

Certainly there are still many prospective areas that can still be used for additional buildings or other equipment, so that in the future we will carry out design development at this stage. It can be said that there are indications of modification in this area later, and indeed the results will be far better than the designs in the picture above which still look simple.

Development Design is a detailed form of the “concept design” which has described the full projection of the front, side and top view of the ship hull or what we usually know as “lines plan”

The making of this “Development Design” was done using Rhinoceros 5.0 software, which also provided the rendered-3D modeling form of the entire ship’s hull as we can see at the picture above.

To start making a ship design, we first made a “concept design” using AutoCAD 2015 software. The dimensions of the overall length (LOA) of the ship have been determined by the KKCTBN committee which is 75 ± 5 cm. The adjustment stage is carried out in searching for dimensions of width (B), height (H), and draft (T) of ships based on references from various sources such as books, journals, and the internet. So that the main dimension of the ship prototype is obtained as follows:

LOA = 78 cm

B = 18 cm

H = 11 cm

T = 4 cm

After the “concept design” is complete, we go to the next stage, the “development design” lets check out our next post!

To face the challenge of supporting the use of Indonesian marine wealth resources, we created a prototype of an electric-powered fast patrol boat. This ship has a deep v planing hull with a chine, and has a wave-piercing concave shape of fore body in order to attain a good performance in terms of speed, and its motion through the obstacle in the operating area.

The main objective of this blog is to provide progress report on design, production, and hydrodynamics analysis of “Fast Electrical Ships with a Remote Control System” prototypes in preparation for participating in “Kontes Kapal Cepat Tak Berawak Nasional” (KKCTBN) 2018 in Politeknik Negeri Madura, East Java, Indonesia.

Not only in English, this blog also has language translation features powered by

Translate that you can access in the footer section.

We will appreciate every feedback from readers of this blog, so don’t hesitate to comment on any posts in this blog. Thank you!

Sincerely,

Team Member of HYD.XDS.RCFB.ANISAH II

-Ervin Hilmy R.

-Rais Rachman H.

-Rizaldy Ilham